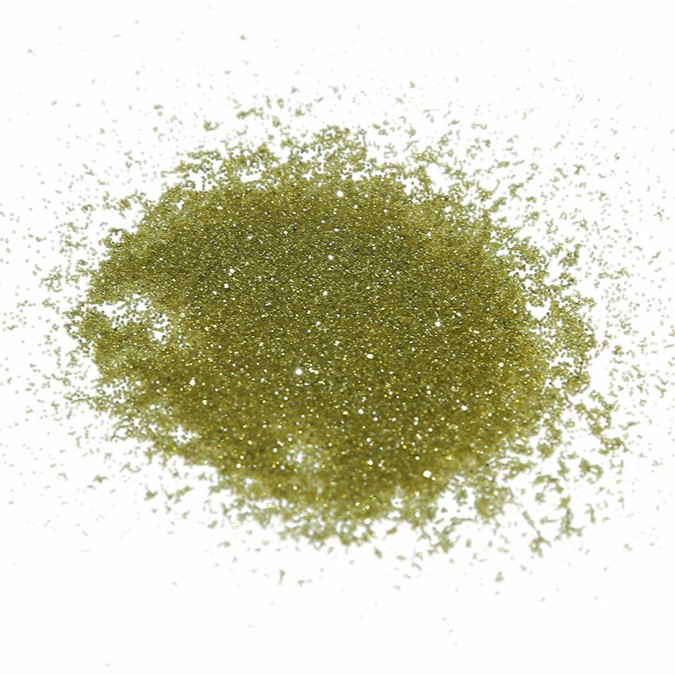

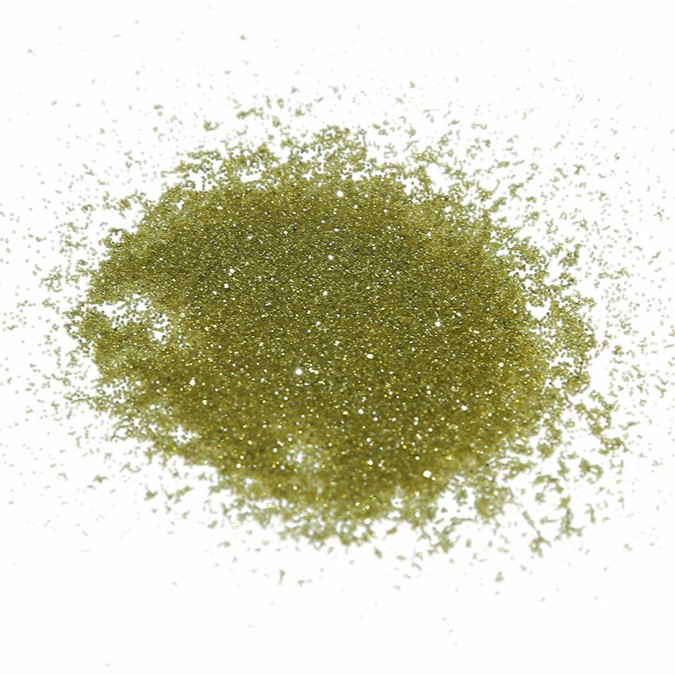

Product Description:

Polycrystalline synthetic diamond powder utilizes good toughness, and can maintain high grinding force while not prone to scratches during the grinding and polishing process. It is widely used in the grinding and polishing of various hard materials such as optical crystals, ceramics, and super-hard alloys.

Product Application:

1.Grinding and Polishing: Due to its extreme hardness and abrasiveness, it is an ideal material for sharpening, grinding and abrasive processes. It is commonly used to sharpen tools, create precision optical lenses, polish gemstones, and prepare surfaces for coating or painting.

2.Cutting and Sawing: Synthetic diamond powder is essential in the production of cutting tools, such as saw blades, wire saws, and drill bits. It provides the necessary hardness and durability required for cutting through materials like stone, concrete, metal, and glass with precision and efficiency.

3.Electronics and Semiconductors: It is utilized for applications such as creating heat sinks, polishing surfaces for integrated circuits, and increasing the efficiency of heat dissipation in high-performance electronic devices.

4.Thermal Management: The outstanding thermal conductivity of synthetic diamond powder makes it an ideal material for thermal management applications. It is used in heat spreaders and heat sinks to efficiently transfer and dissipate heat in electronic devices, power modules, LED lighting, and other high-temperature applications.

5.Lubrication and Coatings: synthetic diamond grit can be used as a lubricant additive due to its excellent friction-reducing properties. It is also used as a coating material on cutting tools to enhance their performance and longevity. The diamond coating provides high wear resistance, reducing the need for frequent tool changes and increasing overall productivity.